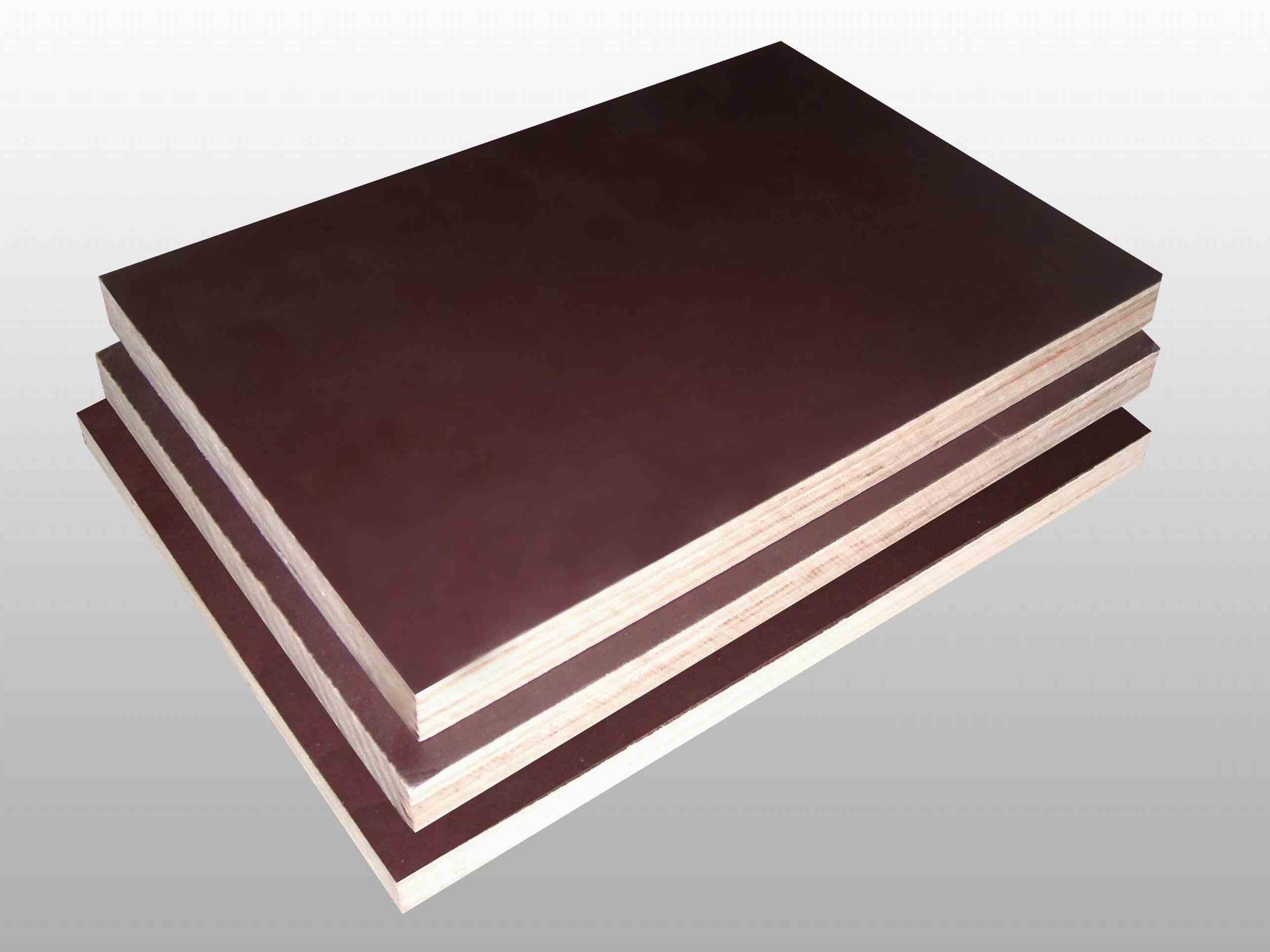

Shuttering Plywood

LEXI Film face densified shuttering plywood is a product for high-end construction users. The phenol film plywood has a coated, glossy surface, which gives the product long life and great value in terms of re-use. This plywood withstands the corrosive action of cement, water and sunlight. An external coating of Phenolic Polymer film made in-house with imported craft paper gives a super smooth, uniform surface finish.

Precautions to enhance the life of film face plywood:

1. Do not drag or drop from height.

2. Stack on flat surface.

3. Clean both side surfaces after use.

4. Apply mould oil after 3-4 uses.

5. Use sealant on cut edges.

6. Use minimum screw to fix the film face plywood.

7. Use putty in the screw holes.

LEXI FFDSP has several advantage over ordinary film faced ply:

• It gives more number of receptions.

• Provides smooth surface to concrete from work.

• It is economical in ratio to its number of uses.

Thickness: 12mm,16mm,18mm and 21mm.

Size: 2440mm * 1220mm

Application: Building,bridges,Heavy Industry & Structures for use on walls,slabs,columns and beams,etc.

|

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

||||||

|

|

|

|

|

||||||

|

|

(after 72hrs. Boiling) Adhesion to piles |

Min. Avg. 1350 N Minimum Pass Standard |

1520 N Excellent |

||||||

|

|

(Dry State) Adhesion to piles |

Min. Avg. 1000 N Minimum Pass Standard |

1250 N Excellent |

||||||

|

|

Glue Sheer Strength |

Min. Ind. 800 N Min. Avg. 1000 N |

1060 N 1250 N |

||||||

|

|

- Along the grain Avg - Across the grain Avg Sum of the Tensile Strength |

32.5 N /sq.mm 22.5 N /sq.mm 60.0 N /sq.mm |

46.5 N /sq.mm 32.2 N /sq.mm 84.7 N /sq.mm |

||||||

|

|

Modulus of Elasticity - Along the grain Avg - Across the grain Avg |

8000 N /sq.mm 4000 N /sq.mm |

9100 N /sq.mm 4320 N /sq.mm |

||||||